APRIL 2024![]()

Process to Change a Specified Anchor

In our blog we explain the steps you should follow to change a specified anchor, along with the importance of following the set process.

Why You Need to Follow the Process to Change a Specified Anchor.

Summary of BS 8539

BS 8539 is the code of practice for the selection and installation of post-installed anchors in concrete and masonry, which has provided guidance since 2012.

However, the new Building Safety Act which came into effect in April 2022 now puts much of BS 8539 code of practice into legislation with a key focus on the competency of duty holders and the collation / archiving of information regarding a building’s safety (The Golden Thread). For contractors to adhere to the new legislation they need to manage information within the The Golden Thread submitted by multiple parties. This includes confirmation of an anchor’s suitability and proof of its correct installation.

Process to Change a Specified Anchor

Step One - Contact the specifier to obtain a copy of the current design spec and required anchor performance data.

Step Two - Contact your supplier / manufacturer, to obtain the performance data of the proposed new anchor and check that in principle it will meet the design spec. Note: BS 8539 recommends only specifying ETA (European Technical Assessment) anchors.

Step Three - Use a design package to confirm the suitability of the proposed new anchor against the design spec (design assessment). Note: Anchor manufactures will typically offer this as a service or provide an online tool, such as Fischer’s C-FIX.

Step Four - Follow the change management procedure set out within BS 8539. Send the design assessment results, which demonstrate the new anchors suitability to the original specifier and pricipal designer for agreement.

Step Five - Follow your projects ‘design change process’ to ensure the design spec is updated to include the agreed new anchors.

Compliant Installation - Once agreed, ensure all the anchors are installed correctly according to the new design spec and following the manufacturers instructions (installers should be trained, use the right tools* and have the required supervision). See section 7 of BS 8539 for further details.

* The right tooling, such as a calibrated torque wrench and the correct setting tool must be used.

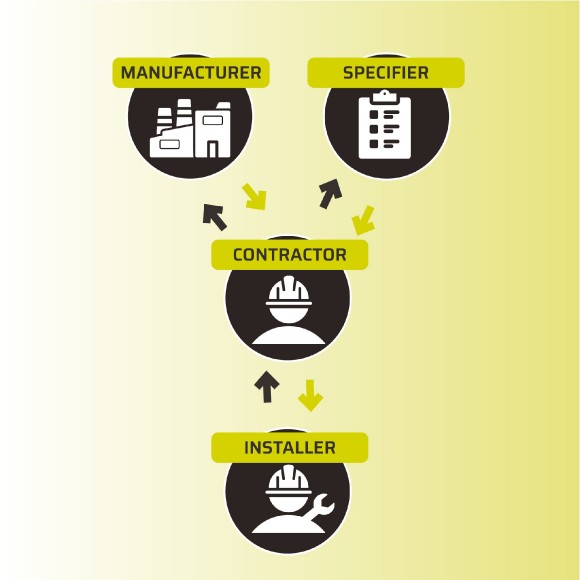

NOTE: In addition to a planned change in anchor, there will always be occasions where conditions on site don’t match the specified design. When this occurs it’s important for there to be communication between the duty holders (installer, constractor, specifier and manufacturer) and that the design spec is updated accordingly.

WARNING: If the contractor makes any changes without approval of the specifier and principal designer, then the contractor will take on the engineering responsibility for the anchor design!

Summary of The Golden Thread

The Golden Thread of information is a term used to describe accurate, trusted, complete and comprehensive records, documented in digital format throughout a project lifecycle.

Anchor Tests Available on Fixmart Products

We can arrange site support and anchor testing for the fixings we supply in accordance with BS 8539. Although please note anchor testing only confirms the integrity of the anchor installation and not the system it’s supporting. Contact our team for further details on 01322 274226 or [email protected]