MARCH 2024![]()

When is Anchor Testing Required?

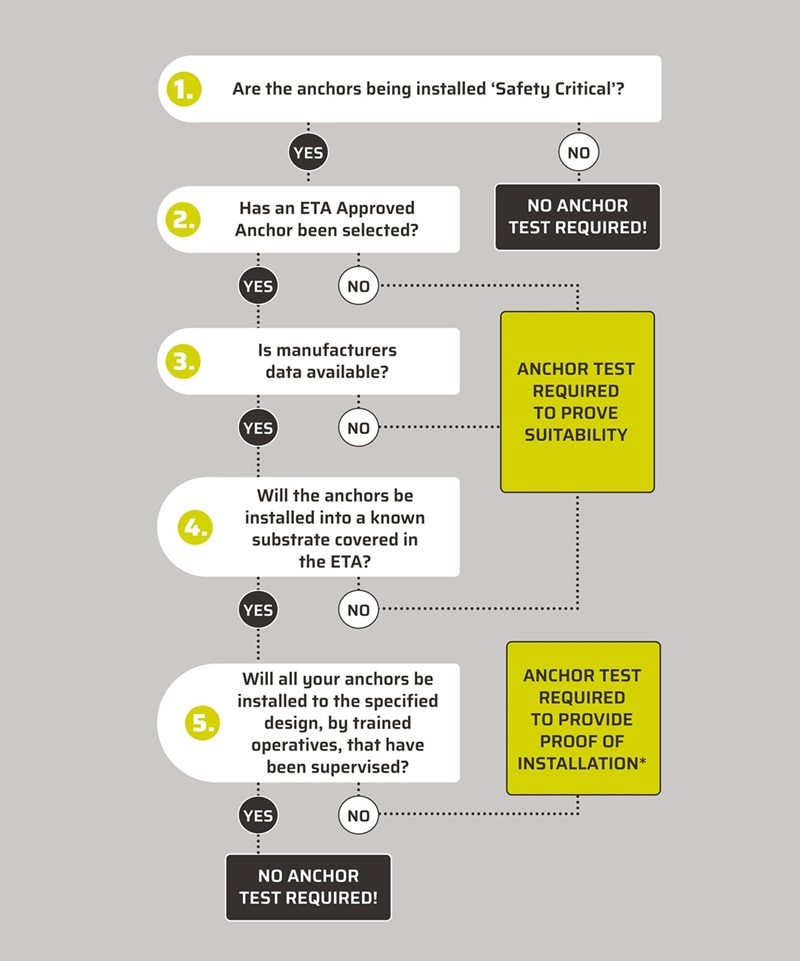

In our blog we explore why anchor tests are increasingly being asked for and whether they are always needed. Plus provide a simple a step by step flowchart to help identify where anchor testing is required.

Why are Anchor Tests increasing being asked for, even though they aren’t necessarily the answer...

BS 8539 - is the code of practice for the selection and installation of post-installed anchors in concrete and masonry, which has provided guidance since 2012.

However, the new Building Safety Act which came into effect in April 2022 now puts much of BS 8539 code of practice into legislation with a key focus on the competency of duty holders and the collation / archiving of information regarding a buildings safety (The Golden Thread).

The Golden Thread of information is a term used to describe accurate, trusted, complete and comprehensive records, documented in digital format throughout a project lifecycle.

For contractors to adhere to the new legislation they need to manage information within the The Golden Thread submitted by multiple parties. This includes confirmation of an anchor’s suitability and proof of its correct installation.

Download our guide for when anchor testing is required here.

Other Common Names for Anchor Tests

Anchor Tests are also reffered to as:

- Pull Tests

- Proof Tests

- Suitability Tests

- Allowable Load Tests

Anchor Testing could be required at two stages of a project:

1. Before the installation of anchors, in order to validate that the proposed anchors are suitable for use in the base material and / or to determine the allowable restistance.

NOTE: Anchor testing is not required when anchors have been installed in accordance with BS 8539 and CFA (Construction Fixings Association) guidance. Any anchor with an ETA (European Technical Assessment) in concrete and masonry will already have published performance data, having undertaken stringent testing. Therefore simply obtaining a design assement from the anchor’s manufacture will be enough to prove its suitability!

2. After installation, when a sample of all anchors may be proof tested to validate the quality of nstallation.

NOTE: Contractors shouldn’t rely on anchor tests as ‘proof’ of correct installation, but instead take advantage of tool box talks from manufacturers and suppliers to ensure their installers are fully trained, use the right tools and are adequately supervised, as this will help prevent the need for testing.

When is Anchor Testing Required?

Notes / further information for each step:

Step 1. Under BS 8539 safety critical fixings should be identified by the specifier. Factors for determining safety critical anchors include: risk of failure, risk to human life, access to the fixing, location of the system being secured and inability to undertake remedial works.

Step 2. BS 8539 recommends only specifying ETA (European Technical Assessment) anchors. ETA is an independent tester which performs standardised tests on anchors in different substrates with various loads. An ETA test document provides trusted performance figures for specifiers to use to make their anchor selection.

Step 3. Manufacturers data ie the published ETA test document and a manufacturers design report demonstrating the anchors suitability to the design.

Note: Many Manufacturers such as Fischer and JCP provide software to quickly and easily obtain a design report.

Step 4. Where the substrate is known (ie for new builds) and covered by the ETA, an anchor test is not required. Only if a substrate is relitively unknown (such as old masonry walls), will a anchor test be required to prove suitability. Or if the category of masonry is ETA approved but doesn’t match or exceed the strength or dimensions of the design.

Step 5. To ensure correct installation, contractors are responsible to provide installers with adequate training (such as a Tool Box Talk) along with all the necessary installation equipment and suitable supervision.

Note: an anchor test doesn’t remove a contractors responsibility to provide the above. The right tooling, such as a calibrated torque wrench and the correct setting tool must be used.

Site Support and Anchor Testing

We can arrange site support and anchor testing for the fixings we supply in accordance with BS 8539. Although please note anchor testing only confirms the integrity of the anchor installation and not the system it’s supporting.

We can also arrange Tool Box Talks for your installers on specific anchors.

For enquires contacts our team on 01322 274226 or [email protected]